Customization has emerged as a critical driver of success in manufacturing. The days of one-size-fits-all products are receding as consumers and organizations alike seek individualized solutions based on their unique requirements and preferences. This shift toward personalization is altering the manufacturing landscape, and organizations that can adapt to this demand will gain major benefits. Custom plastic injection molding is one of the key technologies supporting this shift, allowing manufacturers to create unique, high-quality components that match their clients’ different needs.

The Growing Demand for Customization in Manufacturing

Customization is a developing trend in a variety of industries, including fashion, electronics, automotive, and healthcare. As consumers expect more personalized products, firms must discover ways to accommodate these demands while being efficient and profitable. Customization not only improves client pleasure, but it also provides a competitive advantage for businesses who can provide unique solutions.

The advent of e-commerce and digital platforms has further fueled the customizing trend. Consumers have grown accustomed to individualized purchasing experiences in which they may choose specific features, colors, and patterns. This expectation of personalization extends to the items customers buy, forcing firms to design adaptable production systems that can meet changing client needs.

In the business-to-business (B2B) sector, personalization is equally crucial. Companies in areas such as aerospace, medical devices, and consumer goods require components that fulfill exact requirements to assure product performance and reliability. Custom manufacturing helps firms achieve these aims by providing tailored solutions that meet their specific requirements.

The Role of Custom Plastic Injection Molding in Customization

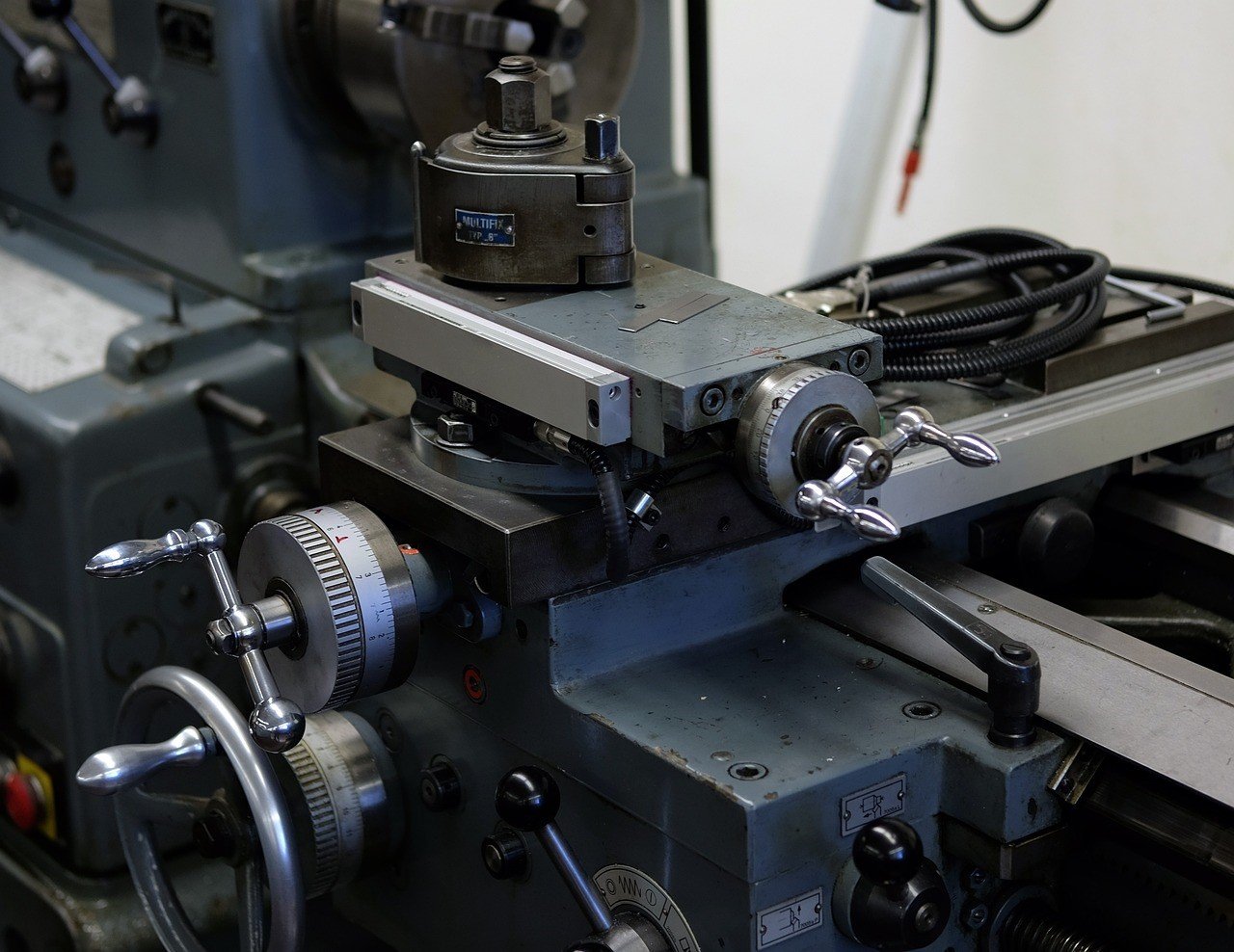

Plastic injection molding is a versatile and commonly used method of making unique components. This manufacturing technique involves pumping molten plastic into a mold cavity, where it cools and solidifies to the desired shape. It expands on this method by allowing manufacturers to make molds that are custom-built to satisfy the particular needs of each client.

Custom plastic injection molding is particularly useful in businesses that require precise and high-quality components. For example, in the automotive business, manufacturers employ custom molds to create sophisticated parts that meet vehicle safety and performance criteria. Similarly, in the medical profession,It is critical for making specialty components like surgical equipment and implantable devices that must follow tight regulatory criteria.

The capacity to develop custom molds allows manufacturers to produce components in a variety of shapes, sizes, and materials. This level of personalization is critical in satisfying the unique needs of clients from various industries. Furthermore, custom plastic injection molding allows manufacturers to optimize component design, increasing usefulness, lowering weight, and eliminating material waste.

Benefits of Customization in Manufacturing

The benefits of personalization in manufacturing extend beyond satisfying client requests. Here are some of the major advantages that manufacturers can gain through customization:

- Increased Customer Loyalty: Customization enables firms to provide items that are specifically tailored to their customers’ requirements. This personalized approach strengthens client connections and enhances customer loyalty since customers are more inclined to return to a brand that knows and meets their individual needs.

- Market Differentiation: In a congested marketplace, personalization allows businesses to differentiate themselves. Businesses can differentiate themselves and attract the attention of consumers looking for something exceptional by offering one-of-a-kind products.

- Improved Product Performance: Customization enables manufacturers to maximize their products’ designs and functioning. Whether it’s improving the ergonomics of a consumer product or increasing the endurance of a component used in industrial machinery, customization leads to better-performing products that meet the specific demands of the end user.

- Cost-effectiveness: While customization may appear to be a more expensive alternative, advances in manufacturing technology, such as bespoke plastic injection molding, have enabled cost-effectiveness even in small production runs. Manufacturers can eliminate material waste, shorten lead times, and reduce total production costs by optimizing the design and manufacturing processes.

- Greater Innovation: Customization promotes innovation by allowing producers to experiment with novel materials, designs, and manufacturing methods. This continual improvement approach produces cutting-edge products that handle evolving industry trends and difficulties.

Overcoming Challenges in Custom Manufacturing

While customization has various advantages, it also poses some problems that manufacturers must overcome in order to remain competitive. One of the fundamental problems is to maintain production efficiency and scalability. Custom manufacturing sometimes takes more time and resources than mass production, which can affect lead times and costs.

To address these issues, manufacturers are increasingly relying on advanced technologies like automation, robots, and additive manufacturing (3D printing). These technologies allow businesses to speed manufacturing, eliminate errors, and increase uniformity, even while producing highly personalized products.

Another problem is ensuring that customized components adhere to the necessary quality requirements. There is limited opportunity for error in areas like aircraft and healthcare, where components must be built to precise specifications. Custom plastic injection molding is critical in solving this difficulty because it provides producers with the accuracy and control required to make high-quality parts that fulfill demanding regulatory standards.

The Future of Customization in Manufacturing

As consumer demand for individualized products grows, personalization will play an increasingly important role in manufacturing. Emerging technologies like artificial intelligence (AI), the Internet of Things (IoT), and data analytics are projected to further transform the customization process by allowing manufacturers to collect real-time data on client preferences and manufacturing performance.

AI-powered design tools, for example, can use user feedback and market trends to create optimized product designs that match specific needs. IoT-enabled manufacturing systems can track production processes in real time, allowing for quick adjustments to assure quality and efficiency. These technologies will allow manufacturers to provide even more tailored solutions while yet keeping the speed and scalability required to compete in today’s industry.

Custom plastic injection molding will remain a critical technology in this evolution, giving manufacturers with the flexibility and precision required to create tailored components that fit the different needs of their clients. As customization becomes the standard rather than the exception, manufacturers who can use these technologies to provide unique solutions will be well-positioned for success.

Conclusion

The trend toward personalization in manufacturing is altering the sector and forcing organizations to reconsider their production procedures. Custom plastic injection molding is at the vanguard of this revolution, allowing manufacturers to build unique, high-quality components that are tailored to their clients’ precise requirements. Businesses that embrace customization can boost customer loyalty, differentiate themselves in the market, and promote innovation, all while reaping cost savings and improved product quality. As technology advances, the capacity to provide individualized solutions that exceed customer expectations will determine manufacturing’s future.