Understanding PLC Programming Languages: A Comprehensive Guide

Programmable Logic Controllers (PLCs) are essential in industrial automation, controlling machinery, processes, and systems with precision and reliability. PLC programming languages are specialized tools used to create software for these controllers. This article delves into the various aspects of PLC programming languages, providing a detailed overview and an FAQ section to answer common questions.

What is PLC Programming?

PLC programming involves writing code that enables a PLC to perform specific tasks. These tasks range from simple operations like switching lights on and off to complex processes involving multiple inputs and outputs, data processing, and real-time decision-making. The language used to write these programs is crucial, as it must be robust and easy for engineers and technicians to understand.

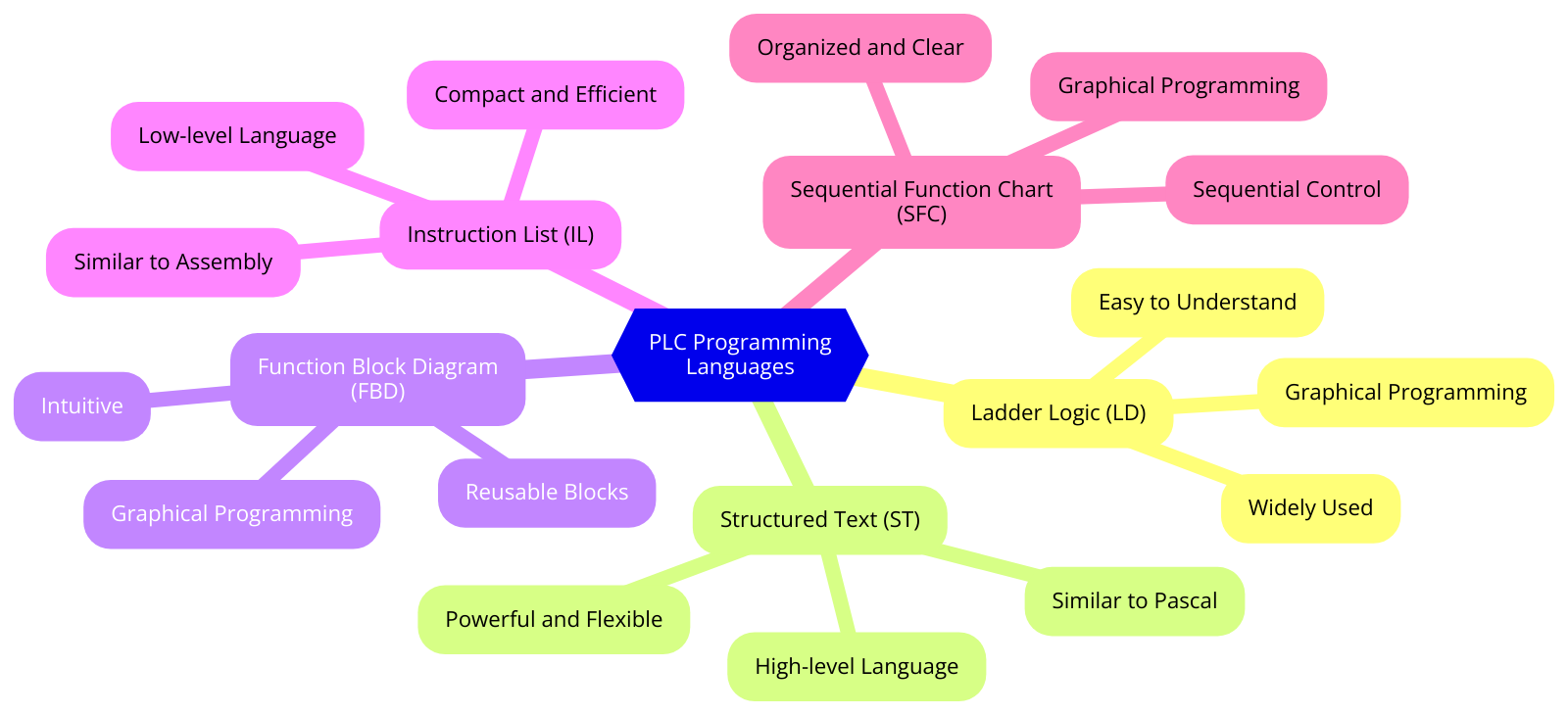

Types of PLC Programming Languages

Several standardized languages are used in PLC programming, each suited for different types of tasks and user preferences. The most commonly used PLC programming languages are defined by the IEC 61131-3 standard:

- Ladder Logic (LAD)

- Description: Resembling electrical relay logic diagrams, Ladder Logic is one of the oldest and most widely used PLC programming languages.

- Advantages: Easy to understand for those familiar with electrical control systems, visual representation simplifies troubleshooting.

- Use Cases: Ideal for simple control processes, such as motor starters and sequential control.

- Function Block Diagram (FBD)

- Description: Uses graphical blocks to represent functions and their connections, much like a flowchart.

- Advantages: Intuitive for visual learners, significant for complex control algorithms.

- Use Cases: Used in process control and automation where complex logic must be clearly visualized.

- Structured Text (ST)

- Description: A high-level programming language similar to Pascal or C.

- Advantages: Powerful and flexible, supports complex mathematical operations and data handling.

- Use Cases: Best for complex algorithms and data manipulation tasks.

- Instruction List (IL)

- Description: A low-level, assembly-like language.

- Advantages: Efficient and precise control over the PLC, suitable for resource-constrained applications.

- Use Cases: Typically used in simple, time-critical applications.

- Sequential Function Chart (SFC)

- Description: Uses a series of steps and transitions to control processes.

- Advantages: Excellent for sequential control and state-based operations.

- Use Cases: Ideal for batch processes, complex sequences, and state-driven tasks.

Why Use Different PLC Programming Languages?

The choice of a PLC programming language often depends on the task’s specific requirements, the process’s complexity, and the programmer’s familiarity with the language. Each language offers unique advantages, and in many cases, a combination of languages may be used within a single project to leverage the strengths of each.

FAQ

Q1: What is the best PLC programming language for beginners?

- A1: Ladder Logic is often recommended for beginners due to its intuitive and visual nature, making it easier to understand and troubleshoot.

Q2: Can I use multiple PLC programming languages in a single project?

- A2: Many PLCs support multiple languages, allowing you to use the most suitable language for different project parts.

Q3: What software is used for PLC programming?

- A3: Software such as Siemens TIA Portal, Allen-Bradley RSLogix, and Schneider Electric’s Unity Pro are commonly used for PLC programming.

Q4: How do I start learning PLC programming?

- A4: Start by learning the basics of Ladder Logic, then gradually explore other languages. Online courses, tutorials, and hands-on practice with a PLC simulator are excellent learning methods.

Q5: What industries use PLC programming?

- A5: PLC programming is used across various industries, including manufacturing, automotive, food and beverage, pharmaceuticals, and energy.

Conclusion

PLC programming languages are a cornerstone of industrial automation, offering various tools to meet the diverse needs of modern control systems. Whether you’re a beginner or an experienced programmer, understanding these languages and their applications is crucial for developing efficient and reliable automation solutions.

Tags

PLC programming, PLC programming languages, Ladder Logic, Function Block Diagram, Structured Text, Instruction List, Sequential Function Chart, industrial automation, programmable logic controller, control systems

By understanding the different PLC programming languages and their applications, you can choose the right tool for your automation projects and improve the efficiency and reliability of your control systems.